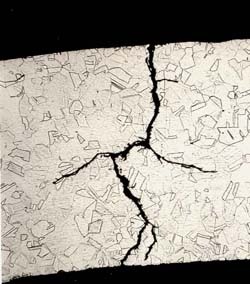

Stress corrosion cracking is known to occur in very weak aqueous solutions containing only a few parts per million of chlorides. The corrosion part of the term is somewhat complex. If the component is already hardened by a manufacturing technique, any subsequent external application of force can push the stress level above the threshold. The figure usually given is 22 on the Rockwell C scale, equivalent to 246 Vickers, not a particularly high value that is easily achieved in practice. There is a direct relationship between strength and hardness, and there is a ‘magic’ hardness value below which stress corrosion cracking is not a problem. The initially soft metal of the fitting is pressed with high force into the lay of the cable, thereby strengthening the joint and imposing internal stress.

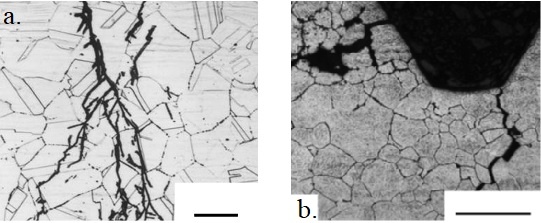

Winter layup is a good opportunity to unstep your mast and inspect your rigging, but don’t forget to check chainplates, bolts and deck fittings as wellĪ good example, shown later in the article, is roll swaging, the process by which the terminal fitting is attached to the wire of a shroud or stay. Internal stress is generated in the manufacturing process, for example a cold stamping operation used for many fittings such as shackles, or high-tensile bolts. Most grades of stainless steel are susceptible and much research effort is expended in trying to improve the performance of this important class of alloys in high-chloride environments.Īn external stress is one that is applied – for example a tightened bolt, tight rigging or component under tension. Stress corrosion cracking, as the name suggests, is one of those failure mechanisms that relies on a combination of two factors.Įither stress or corrosion alone would not cause the failures that are described in the article.įurther to that there is a threshold temperature below which the problem should not occur. To be technically correct, I am discussing the version of it that occurs in chlorides (such as salt water), whereas another that occurs in sulphides can be ignored for this article. In similar fashion to fatigue cracking, stress corrosion cracking is one of those failure mechanisms that can remain hidden for a long time, suddenly giving way when stress levels cross a certain threshold which, as is the way of these things, is usually at the most inconvenient time for the yachtsman. However, some means by which metal parts can break remain somewhat more clouded in mystery, few more so than stress corrosion cracking. Vyv Cox is a chartered engineer and has been sailing for more than 50 years

0 kommentar(er)

0 kommentar(er)